Part 1: Mastering Can-Seam Quality

August 21, 2023

How can-seam materials impact TPO

Who can resist a breath of fresh mountain air? While oxygen benefits your body and mind, it’s not a canner’s best friend. In fact, total package oxygen (TPO) can affect both your canning materials and your machines. In this blog post, we’ll explore how can-seam materials can impact your total package oxygen levels and what you can do about it.

But first:

What is total package oxygen?

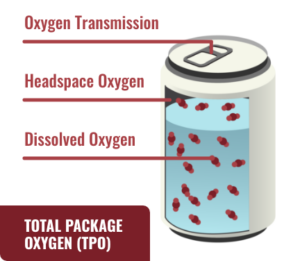

At RSS MACLIN, we support everyone in the food and beverage packaging industry, from micro-breweries to carbonated beverage giants. For those new to the industry, total package oxygen is the amount of oxygen that is sealed in a package. For cans, this includes:

- Dissolved oxygen: The oxygen that is dissolved in the liquid itself

- Headspace oxygen: The oxygen within the foam of a carbonated beverage

- Oxygen transmission: Oxygen that slowly permeates through the walls of the can

At RSS MACLIN, we’re committed to excellence.

How do can-seam materials affect TPO levels?

The materials used for can seaming are important to ensure low TPO and a high-quality seal. When exploring how can-seam materials affect TPO, we’ll look specifically at the compound, can body, and seam specifications.

Compound

Compound quality and consistency

When you’re trying to ensure a quality seam on your can, compound is crucial. It’s a vital part of the sealing process and ensures an airtight and secure seam with low TPO levels. Be sure to check the consistency of the compound to ensure optimal quality, since that can also impact the quality of the seam and the TPO levels.

Compound amount

In addition to the quality of the compound, it’s also important to ensure the right amount of compound is applied to each lid. For the best results, apply 26-32 grams of compound, depending on the diameter of the lid.

Can body

Materials

In the food and beverage packaging industry, aluminum is the material of choice, often selected for its corrosion resistance and lightweight properties. Over time, aluminum cans are susceptible to oxygen transmission, where the oxygen passes through the material and into the can’s liquid, increasing the TPO levels. For this reason, it’s important to use materials that are new, as the age of the material can impact the TPO levels. At RSS MACLIN, we recommend using lids that are no more than 2 years old, so as not to compromise the quality of the seal.

Can dimensions

At RSS MACLIN, we know that details matter. When you ask for scheduled or emergency service, we look at more than just the equipment. Your can’s dimensions are crucial to accurately determine the pin height so that the can seam is shaped and sealed correctly. To calculate the pin height, use the following equation:

Pin height = Raw can height – Chuck lip height – Material loss – Material deflection

Seam specifications

Curl height

The can seam’s curl height can help minimize TPO levels and improve the quality and integrity of the seal. While curl height varies according to the can’s dimensions, it’s important that seam technicians regularly inspect the seam quality and adjust as necessary.

Flange angle

As a critical aspect of the seam, the flange angle provides strength to ensure that the seam is able to withstand the internal pressure of carbonated beverages without compromising the seal. If the flange angle isn’t correct, the seam could leak, leading to increased TPO, decreased freshness, and possible product contamination.

Take your can seams to the next level

Don’t let inconsistent can–seam quality hold you back. Sign your team up for our hands-on can–seaming training to learn how to inspect, identify, and correct issues to ensure ultimate product freshness and customer satisfaction.

RSS MACLIN, an emerging packaging solutions provider, will present its expert can seamer and filler services and products at Pack Expo Las Vegas 2023

Previous BlogNext Blog Title

Next Blog