Understanding Double Seam Can Defects: Types and Their Impacts

July 22, 2024

In the world of packaging, particularly in the food and beverage industry, the integrity of a can’s seam is crucial. The seam, where the can’s body and end are joined, must be perfect to ensure product safety, quality, and longevity. However, defects with a double seam are common issues that can compromise the contents. In this blog, we’ll explore the various types of can-seam defects, their causes, and how they can impact both manufacturers and consumers.

Types of Double Seam Defects

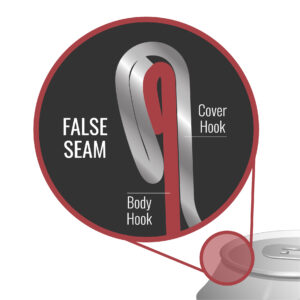

1. Incomplete Seam (False Seam)

What is it?

An incomplete double seam, often referred to as a false seam, occurs when the seam is not fully formed, leading to gaps between the can body and the end.

Causes:

- Misalignment of the can body and end during the seaming process

- Insufficient pressure during the seaming operation

- Worn or improperly adjusted seaming rolls

Impact:

This defect can lead to leakage, contamination, and compromised product integrity. For consumers, it poses health risks, while manufacturers face recalls and brand damage.

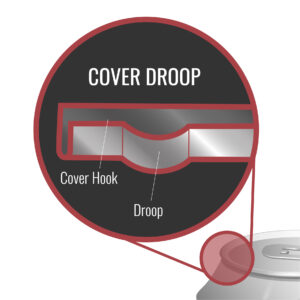

2. Droop

What is it?

Droop is a defect where the metal at the seam’s edge hangs downward, creating an uneven edge.

Causes:

- Excessive metal being fed into the seam

- Improper adjustment of seaming rolls

- Incorrect can end size for the body

Impact:

While droop might not always lead to immediate leakage, it can create weak points that may rupture under pressure, leading to potential contamination and product spoilage.

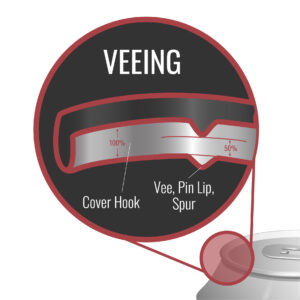

3. Vee

What is it?

A vee defect appears as a V-shaped gap or indentation in the double seam, typically at the seam’s side.

Causes:

- Incorrect alignment of the seaming rolls

- Excessive or insufficient pressure during seaming

- Damaged seaming tools

Impact:

This defect significantly increases the risk of leakage and spoilage, potentially leading to consumer complaints and financial losses due to returned products.

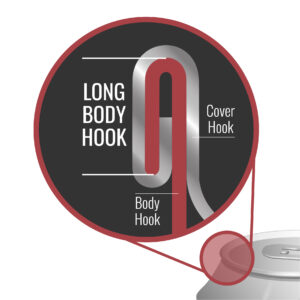

Cover Hook Defects

What is it?

When the cover hook exceeds or is below the Can manufacturer specification listed on the OEM Specifications sheet.

Causes:

- Misadjusted seaming rolls, primarily 1st operation

- Worn or failed 1st operation rolls

- Worn-out seaming chuck

- Excessively long body hook

- Material issue

Impact:

Cover hook defects can lead to unbalanced or fractured seams resulting in leakage or holding product.

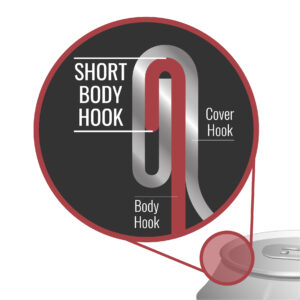

Body Hook Defects

What is it?

When the body hook exceeds or is below the can manufacturer specification listed on the OEM specifications sheet.

Causes:

- Total machine pin height

- Individual station pin height (seaming chuck or lifter chuck plane)

- Excessively long cover hook

- Tight or loose 1st operation roll

- Spring pressure

- Material

Impact:

Body hook defects lead to fractured seams, unbalanced seams, and low overlap resulting in leakage or hold product

5. Seam Cutover

What is it?

Seam cutover is a condition where the seaming tool cuts into the double seam, creating a sharp edge and thinning the metal.

Causes:

- Excessive compound

- Improperly adjusted tooling (often an excessively tight 2nd operation or worn-out 1st)

- Overly hard seaming rolls

Impact:

Cutovers can cause immediate leakage and present a safety hazard to consumers due to sharp edges. For manufacturers, this defect leads to significant waste and potential liability issues.

Ensuring Seam Integrity

In conclusion, understanding and addressing the defects of a double seam is vital for the packaging industry. RSS MACLIN provides support in the maintenance of can seamer machines, proper training for operators, and stringent quality control measures that can help mitigate these issues. By recognizing the types and causes of these defects, manufacturers can take proactive steps to ensure their products remain safe, high-quality, and reliable for consumers.

If your business needs assistance with a can seam, double seam or can seamer machine, please contact us today.

The Benefits of Choosing an Expert Can Seamer Auditor

July 22, 2024

In the world of manufacturing and packaging, precision is paramount. This is especially true for can seamers, which plays a crucial role in ensuring product quality and safety. Regular audits by an expert can seamer auditor are essential to maintain optimal performance and prevent costly downtime. One company that stands out in this field is RSS MACLIN, known for its comprehensive and meticulous auditing services.

Here’s four reasons why choosing an expert can seamer auditor, particularly RSS MACLIN, can make a significant difference for your operations.

1. Enhanced Inspection with 30% More Checkpoints

One of the key advantages of choosing RSS MACLIN for your can seamer audits is their commitment to thoroughness. They incorporate 30% more checkpoints in their seamer machine inspection process compared to standard practices. This means that every aspect of your can seamer machine is examined with greater detail, ensuring that potential issues are identified and addressed before they escalate into major problems.

More checkpoints mean a more comprehensive understanding of your equipment’s condition. This detailed inspection helps to maintain the highest standards of quality and performance, reducing the risk of product defects and recalls. With RSS MACLIN, you can have peace of mind knowing that your can seamer machines are in top-notch condition.

2. Comprehensive Parts List Generation

Another significant benefit of choosing RSS MACLIN is our ability to generate a detailed can seamer parts list during the audit. This list includes all components that may require maintenance or replacement, simplifying inventory management and ensuring you always have the necessary parts on hand to keep your can seamers running smoothly.

After performing the audit, we generate a comprehensive can seamer parts list that covers everything needed for the section, not just the critical parts that failed. This includes components surrounding the assembly that are naturally compromised during service. Our thorough understanding of the can seamer parts allows us to cross-reference your inventory, helping you avoid duplicate purchases.

3. Expertise in Repairs

In addition to their auditing capabilities, RSS MACLIN also offers repair services that are not limited to specific assemblies but encompass the whole seamer machine. This means that any issues identified during the audit can be promptly addressed by our skilled technicians. Having the same team handle both the audit and repairs ensures consistency and quality in the service provided.

Our expertise in can seamer repairs means that problems are resolved efficiently and effectively, reducing the risk of recurring issues. By entrusting your repairs to RSS MACLIN, you benefit from their deep understanding of can seamer systems and their commitment to maintaining high operational standards.

4. Facility/technician growth

Our technicians are not only knowledgeable but also personable and give your facility the opportunity to receive hands-on experience during the audit. They provide the experience needed and act as mentors, guiding your staff to become self-sufficient. Our technicians focus on teaching your personnel the intricacies of the audits while providing coachable moments to help improve the overall performance of your facility. Schedule a training session with the experts so your team can efficiently address can seamer issues and increase your O.E.E.

Why Choose RSS MACLIN?

RSS MACLIN stands out in the industry for several reasons:

- In-Depth Knowledge and Experience: Their team of auditors and technicians possess extensive knowledge and experience in can seamer systems, ensuring accurate diagnostics and effective solutions.

- Advanced Tools and Techniques: They utilize state-of-the-art tools and techniques to provide the most thorough audits and repairs possible.

- Commitment to Quality: With a focus on quality and customer satisfaction, RSS MACLIN ensures that your equipment performs at its best, enhancing your overall production efficiency.

We are your one-stop shop for everything from parts procurement and audits to entire machine repairs and consulting across the line.

Your Trusted Can Seamer Auditor

Choosing an expert can seamer auditor like RSS MACLIN can have a profound impact on your production operations. With 30% more checkpoints, detailed parts list generation, and the ability to perform full-machine repairs, RSS MACLIN provides a comprehensive solution to keep you can seamers in optimal condition. Invest in expert auditing services to protect your equipment and maintain the highest standards of operational excellence. Learn more about our auditing and overhaul services.

Case Study: How Berlin Packaging Helped Their Clients Reduce Downtime with Can-Seam Analysis Training

July 18, 2024

RSS MACLIN has over 75 years of expertise in packaging and can seamer maintenance. Berlin Packaging came to RSS MACLIN to help their customers with maintenance issues and to understand the knowledge of can seaming. The customer does not manufacture the can seamers, but wanted their customers to receive the proper training for maintenance teams to understand how can seamers operate, and how to effectively address issues as they arise.

Can-Seamer Issues

Berlin Packaging stated that 95% of the issues their clients were having were leaking cans (a.k.a. seam issues). As the relationship evolved, they would also call RSS MACLIN to help troubleshoot when cans began jumping on the line. The client would also send RSS MACLIN samples of what the bottlenecks were, and they would come to their various clients to evaluate and troubleshoot the issues.

Can-Seam Analysis Training

RSS MACLIN provided Berlin Packaging with a three-day, in-house, Can-Seam Analysis training class that was beneficial for helping their clients troubleshoot problems. The class itself provided in-detail training about can seamers, maintenance, and more. They described the class as “interactive” and “informative.”

RSS MACLIN’s goal is to help maintenance teams update skills and knowledge, stay current on new technologies, and address problems quickly and effectively through the training courses.

Interactive

Berlin Packaging is a “huge supporter of RSS MACLIN” and says, “This is an awesome class. All clients need this.” Each maintenance person who took part in the training gets hands-on experience with the can seamer to make sure they feel confident that they can assist their clients with troubleshooting issues.

Informative

There is a class-style aspect to the three-day course. The client appreciated that the experience was both informative and engaging, keeping them alert and interested. Even if you are knowledgeable about can seamers, this class is great for a refresher and to follow up on evolving can-seaming technology.

Why Choose RSS MACLIN

Let us help your team increase your O.E.E. (Overall Equipment Effectiveness) and stay productive. We offer in-house at our facility or on-site training sessions. Schedule a training session today.

Part 2: Mastering Can-Seam Quality

July 9, 2024

From becoming a student to a master, it is not enough to understand the theory, but the applied principles behind each component of the seam. In Part 1 of Mastering Can-Seam Quality, we discussed how can-seam quality (specifically, total package oxygen or TPO) is impacted by the materials used. Though we’re biased, we think it’s worth your time.

But materials aren’t the only thing that makes or breaks can-seam quality. In Part 2: Mastering Can-Seam Quality, we’ll discover the impact of the packaging process and the key factors that affect the quality of can seams. By understanding and implementing these factors, you can meet your standards of quality and productivity at the same time.

Correct Tooling and Condition

The foundation of a quality can seam lies in using the correct tooling. Avoid taking shortcuts; instead, prioritize an investment in high-quality tooling from manufacturers that uphold stringent tolerances, to ensure precision not only in profile but also in bearing assemblies. Remember to select the correct coating for your application needs and verify that the manufacturer applies the coating correctly.

It’s critical that the tooling is regularly maintained, as deteriorated tooling can lead to uneven seams, leaks and result in hold product or unscheduled downtime. To avoid these problems, be sure to have your can seamer tooling inspected and maintained regularly. This will ensure that your tooling is free from cracks, chips, and regular wear and tear. Furthermore, the rolls shouldn’t have a “Roll Rock” of more than .002.

At RSS MACLIN, we provide can-seamer audits, which include a roll inspection, so you can stay ahead of maintenance issues and ensure a high-quality seam. When you partner with RSS MACILN, we’ll take full responsibility for the audit, procurement of parts, and repair. Not only that, but we’ll get you back up to maximum efficiency in no time.

Proper Can-Seamer Set-Up

Another fundamental aspect of mastering can-seam quality is ensuring the seaming machine is properly set-up. During this process, be sure to align and calibrate the machine, tighten the fasteners, and verify the correct settings for can and lid specifications. The correct timing and machine guide rail set up is crucial to deliver the open can into the seamer without can damage.

The attention you devote to this phase will directly affect the accuracy and quality of your seam and have a direct impact on the number of defects on your can-seamer line.

Sound basic? It is. Every can-seamer technician starts somewhere. If you have new members on your team, make sure they get the training they need to succeed. Reach out to us to schedule can-seamer training for your team.

Smooth Can & Lid Transfer

During the dry cell phase, before the cans are filled, it’s important to address any disruptions that might affect the can-seaming process.

Be sure you have a smooth, clean transfer of cans from the depalletizer to the can-seamer machine to obtain a high-quality seam. If any debris or clutter is introduced during the transfer to and from the can-seamer machine, it is sure to impact the integrity of the seam. This can lead to leaks, downtime, and lost profit. To avoid this, maintain a clean workspace around the can-seamer machine.

Before the wet cell, your depalletizer and conveyance’s guide rails and transfer speeds must be set up properly to avoid damaging the can body flange. Ensure a clean Transfer reduce tipping and confirm that the guide rails are properly aligned.

Level Up Your Can-Seam Quality

Don’t waste another dollar on lost product or production time. Reach out to RSS MACLIN. As the can-seamer experts, we’ll help you master your can-seam quality to achieve ultimate productivity, freshness, and customer satisfaction.

Monthly Guide for Can-Seamer Maintenance

June 17, 2024

Performing regular monthly can-seamer maintenance checks is crucial to keeping your can seamer in top condition. By dedicating time to these important checks, you are being proactive and addressing any issues before they escalate. This saves your business time and money on repairs. With over 75 years of collective experience, we’ve gathered a detailed list of monthly maintenance checks to keep your can seamer running efficiently.

Monthly Maintenance Checks

Before beginning this monthly regiment, using your OEM manual, confirm that you have all oil weights and recommended gasket/sealant on site.

Oil Filtration System

First and foremost, always make sure your lubrication panel is clean and free of debris. This ensures an easier inspection of the system. Confirm there are no leaks, that flow is present, and if pressure exceeds the OEM recommendation to replace filters.

Gearbox Inspection

Check for Oil Levels

Check all gearbox oil levels in the can-seamer and add or replace oil as needed. Lubrication will extend the lifespan of the components and reduce friction. Also want to look for foreign liquid infiltration such as beer, water, sugar etc. in your oil.

Inspect Gears for Wear

If the gears show signs of wear, such as pitting or chipped teeth or backlash, evaluate, document, and photograph any issues for future modular repairs.

Motor and Drive System

Verify Motor Mounting and Alignment

To ensure functionality, verify the motor mounts and alignment. Inspect integrity of motor mount support. If time allows, use a dial indicator to verify the motor is properly aligned. This will be critical in keeping drive trains from developing backlash/premature wear.

Inspect Drive Belts for Tension and Wear

Inspect drive belts for tension and wear and replace them to maintain optimal performance. When reviewing your drive belts, look for splitting, cracking, chipping of belt cogs, as well as dry rot. If any of these conditions exist, replace belt before properly tensioning. *Pro-tip: If clearance is available and the assembly does not interfere, install additional cog belt to minimize downtime for future belt swaps.

Electrical System Check

Inspect Wiring for Wear or Damage

Inspect all wiring for cracks and the ability to be securely fastened. If time allows, replace said wiring or sensors if physical damage is present. Verify each whisker and Prox switch are illuminating properly and/or registering on the filler/seamer HMI.

Test Emergency Stop and Safety Features

A widely overlooked check is the functionality of all machine e-stops. Not only is it important to verify each one works properly, but that they register on the filler/seamer HMI accurately.

Schedule Preventative Maintenance

At RSS MACLIN, we offer comprehensive maintenance plans tailored to your specific needs. Don’t wait for issues to arise. Keep your can seamer up and running for many years by scheduling monthly preventative maintenance checks. Reach out to RSS MACLIN today, for a full-service solution to can-seamer maintenance.

Find a Can-Seamer Audit You Can Trust

April 23, 2024

Precision and reliability are paramount in can-seamer technology. At RSS MACLIN, we take pride in setting new standards with our Can-Seamer Audit Process, a meticulous and comprehensive approach that goes above and beyond industry norms. Our commitment to excellence is evident in the 30% additional points of inspection incorporated into our audit process, ensuring the highest quality and performance for every can seamer.

Unmatched Expertise

One of the cornerstones of our Can-Seamer Audit Process is the ownership of the entire lifecycle – from inspection and parts list generation to procurement and the actual overhaul while providing thorough documentation and records of the process. Unlike conventional practices that may involve multiple entities, our seamless approach allows us to maintain control and accountability throughout the entire process. This end-to-end ownership ensures a streamlined and efficient overhaul process, minimizing downtime and maximizing productivity for our clients.

Industry-Leading Inspection Standards

Meticulous attention to detail sets the RSS MACLIN Can-Seamer Audit Process apart. We have integrated 30% more inspection points than the industry standard, demonstrating our unwavering commitment to precision and quality. Our inspectors, armed with state-of-the-art tools and technology, leave no stone unturned, thoroughly assessing every aspect of the can seamer to identify potential issues and areas for improvement.

A Team of Seasoned Experts

At the heart of our Can-Seamer Audit Process is our team of seasoned experts, boasting over 75 years of collective industry experience. These professionals bring a wealth of knowledge in the can-seamer industry and the broader spectrum of production line operations. Their expertise extends beyond the seamer, allowing them to understand the intricate relationships between different components and ensuring a holistic approach to the audit process.

Continuous Improvement and Innovation

In an ever-evolving industry, staying ahead of the curve is essential. At RSS MACLIN, we meet current industry standards and strive to set new benchmarks through continuous improvement and innovation. Our team is dedicated to exploring cutting-edge technologies and methodologies to enhance can seamers’ efficiency, reliability, and performance, ensuring our clients always receive the best solutions.

Schedule a Can-Seamer Audit

If you’re looking for a comprehensive solution to maximize your production time, contact RSS MACLIN to schedule a can-seamer audit. When you partner with RSS MACLIN, we’ll help elevate your can-seamer process and propel your production line to new heights of efficiency and reliability.

The Ultimate Checklist for Weekly Can-Seamer Maintenance

April 19, 2024

Weekly Maintenance Tasks

Can-seamer maintenance is top of mind for a reason. It’s the best, most efficient way to keep your production line up and running. With more than 70 years of collective experience on the seamer line, our team knows a thing or two about keeping your can seamer in top shape. In this blog, we’ve outlined a detailed list of what to check each week to ensure your can seamer runs efficiently.

Inspection of Transfer Chains and Drive Belts

Let’s start with the transfer chain:

Clean Transfer Chain: Begin by cleaning the transfer chain to facilitate an easy inspection a clean surface allows for an effective assessment and helps maintain the seamer’s performance.

Inspect Wear Strips: Carefully inspect all wear strips for the transfer chain. Any signs of wear or damage should be noted, fasteners should be present and secure, and replacements should be made promptly to maintain optimal function.

Adjust Transfer Chain Tension: Ensure that the transfer chain is adjusted to the proper tension. Proper tension is crucial for smooth operation and accurate seaming.

Assess Transfer/Chain Fingers: Check the transfer/chain fingers for sharp edges or damage. Any issues found should be addressed immediately to prevent potential problems during the seaming process.

Verify Synchronization: Verify and record the synchronization at the filler transfer and at the can make-up in the seamer . This step ensures precise operation and optimal seam quality. If you need parts or have questions about specific chain tolerances, feel free to reach out to us.

Now, let’s move on to the drive belts:

Assess Belt Condition: Examine the belts for any signs of stretching or cracking at the filler and lid separator, if applicable. Damaged belts should be replaced to prevent unexpected breakdowns and maintain consistent performance.

Synchronize Driven Assemblies: Ensure that all driven assemblies are synchronized properly. Proper synchronization enhances the can seamer’s efficiency and reliability.

Align and Tension the Belt: Align the belt and adjust its tension to the manufacturer’s specifications. This step is important to achieve consistent seams and optimal results.

Chuck and Rolls

Let’s address the chucks and rolls. By now, your seaming technician team is probably following our daily maintenance checklist for your can seamer. If any chucks or rolls showed premature wear or are trending towards failure during the daily check, it is crucial to replace them promptly. By taking proactive measures, you can prevent further damage and maintain the machine’s performance.

Now let’s focus on your weekly maintenance check for chucks:

Use a Dial Indicator: Use a dial indicator to record the current plane of all machine stations. This consistency and tight tolerance are critical for achieving consistent seams.

Does your team need can-seam analysis training? We’ll teach them how to identify can damage and how to prevent it. Schedule your training today.

Verify and Record chuck plane: Using your dial indicator, verify and record each station starting with 1, indicating the amount of variation between each station. Optimal setup should be +- .001 . Accurate records allow you to track changes over time and address any issues promptly.

Verify Knockout Pad: Asses all K.O. Pad conditions for any type of damage. Then using your RSS MACLIN Pin Gauge record all machine stations and adjust the height if outside of OEM Specification. Note: If any chucks are replaced, verify that the KO pad is seated and secured properly. Take care not to over-torque, as it can lead to potential problems during operation. Then set to proper height.

For rolls:

Assess Roll Rock: Using your dial indicator, assess the roll rock on all remaining first and second operations to ensure it is less than .002. If the roll rock exceeds .002, it’s important to replace the roll to maintain precise seaming.

Assess Roll Condition: Assess the coating of the roll. While performing this inspection confirm there are no cracks, chips or grooves on the profile

Lubrication

During your daily maintenance check, did you find any signs of leaking lines? If you find leaks, confirm that all unions are tightened and secured properly. Proper lubrication is crucial for smooth operation and extended machine life.

Ensure Lubrication Block Functionality: Verify that the lubrication block is functioning correctly(confirm the cycle pin and sensor.) If there are any faults, it might indicate a blockage or failure in the distribution block.

Assess for Blockage: Assess whether the blockage can be cleared or if a replacement is needed.

Audit the Condition of Oil: Regularly audit the condition of the oil, especially for signs of contamination, such as sugar, water, or product.

Importance of A Can-seamer Audit: A can-seamer audit can indicate potential machine failure leading to a decrease in its lifespan. If you don’t have an audit on your calendar this year, reach out to RSS MACLIN to learn why so many large food and beverage companies and microbreweries trust us for their can-seamer audits.

Schedule Preventative Maintenance

Keep your can-seamer machine operating at its best by scheduling preventative maintenance for your can-seamer line. Don’t wait for issues to arise. When you choose RSS MACLIN for your maintenance, we’ll create the parts list, procure the parts and repair your seamer. Reach out to RSS MACLIN today, for a full-service solution to can-seamer maintenance.

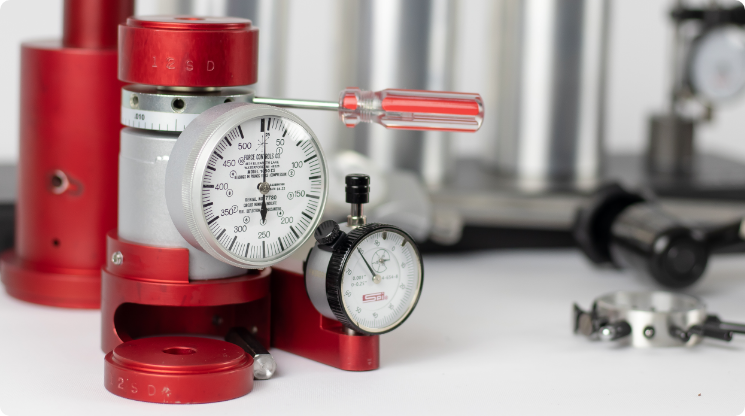

The Importance of a Spring Pressure Gauge

April 4, 2024

As a can seamer technician, you understand the critical role precision plays in maintaining the integrity of canning operations. Any inconsistencies in the sealing process can result in damaged cans, leading to costly rework and potential product recalls. One tool that can help you prevent such mishaps and ensure optimal performance is a spring pressure gauge. In this blog, we will explore why you should consider utilizing this essential instrument and how it can enhance your can seaming process.

Precision Maintenance

Using spring pressure gauges eradicates pressure variations inside your can seamer from station to station, thus creating consistent seams. By eliminating guesswork in lifter spring pressure adjustments, adherence to OEM specifications is upheld. Reliable pressure readings facilitated by these gauges translate to enhanced system accuracy.

Uniformity Assurance

Using spring pressure gauges eradicates pressure variations inside your can seamer from station to station, thus creating consistent seams. By eliminating guesswork in lifter spring pressure adjustments, adherence to OEM specifications is upheld. Reliable pressure readings facilitated by these gauges translate to enhanced system accuracy.

Quality Control

Accurate pressure monitoring is crucial for ensuring health, safety, and product quality. Seam variations in can seaming may compromise warranties, induce leaks, or pose safety hazards. Regular pressure monitoring afforded by spring pressure gauges enables prompt response to fluctuations, averting potential issues and optimizing operational efficiency.

Alignment with RSS MACLIN

Leveraging spring pressure gauges from RSS MACLIN minimizes downtime, reduces waste, and optimizes production processes to yield consistent, high-quality outcomes. Explore our comprehensive Spring Pressure Gauge Kit for further insights.

Discover what our Spring Pressure Gauge can do for you can-seamer line

With the RSS MACLIN Spring Pressure Gauge, you can trust that a vital aspect of the seam remains consistently precise, providing you with peace of mind throughout your operations.

How to Make Your Changeover Like a Pit Crew

February 23, 2024

NASCAR has managed to shave the hours of car maintenance down to mere seconds. Like a race car pit crew, RSS MACLIN understands that on the can-seamer line, efficiency isn’t just convenient; it’s a necessity. Buckle up. In this blog, we’ll explore how we can make your can diameter changeover team operate like a pit crew.

At RSS MACLIN, we’re not stopping to refuel or change tires. We’re stopping the whole production line, which is just as disruptive. An average can diameter changeover for a can-seamer machine takes 8-12 hours. If you follow our lead, you can cut that tooling changeover down to four hours.

The Problem

When pit crews work on cars, they’ve got seconds to diagnose potential problems. At RSS MACLIN, the problems are different, but the clock is still ticking. That’s why we’re committed to solving the following problems as quickly and efficiently as possible:

Time-Consuming Changeovers

Installing change parts, especially those for can diameters, can be time-consuming. We’ll help you streamline this process by pinning your machine guide rails, using our Quick-Change Timing Plug and chain fixture and Oversized Hollow Plugs. Instead of spending time installing change parts, you can use that time and energy on the production line.

Risk of Equipment Damage

When the clock is running and you rush through changeovers, you run the risk of damaging your equipment. In fact, some machine parts that are susceptible to damage can affect the integrity of the seam. At RSS MACLIN, our expertise and SOPs (standard operating procedures) ensure proper handling and installation, minimizing the risk of costly equipment repairs or replacements.

Quality Issues and Production Delays

Can diameter changeover is one challenge. The ramp-up into full production is another challenge that can bring quality issues and delays in meeting production demand. At RSS MACLIN, we can enhance your quality control measures and reduce the downtime associated with ramp-up, because a meticulously thought-out process and execution beats a reactionary plan any day.

The Solution

At RSS MACLIN, we’re proud to provide can-seamer audits with 30% more inspection points than OEM. What’s more, we take a look at the entire packaging line (not just the seamer), the technicians, and the materials, to give you the most thorough can-seamer audit on the market.

The Crew

Part of what makes a NASCAR pit crew so successful is having the right person for the right job. They are a highly trained team that carries out specialized tasks like clockwork.

At RSS MACLIN, we can train your team to become can-seamer experts with our hands-on three-day training that is offered on-site.

The Material

At RSS MACLIN, our team efficiently stages can-handling parts for easy accessibility, while also using clear markings to identify parts and diameters. This helps reduce confusion and time searching for specific can diameter sizes to improve efficiency and guarantee a perfect setup every time.

The Process

A documented changeover process is crucial to minimize inefficiencies on your can-seaming line, by creating a clear path using a step-by-step method for repeatability and consistent results. This systematically removes more variables that can affect your perfect can seam and body

Contact RSS MACLIN

It can take can-seam teams an entire shift to change the can-handling parts and upwards of two shifts to optimize the new configuration for efficiency. With the right crew, material and methods, we won’t just have your can diameter changed in four hours, we’ll have you running at peak efficiency.

Let’s get efficient! Contact the can-seamer experts to develop the pit crew process your company wants when changing the can-seamer.

Part 1: Mastering Can-Seam Quality

August 21, 2023

How can-seam materials impact TPO

Who can resist a breath of fresh mountain air? While oxygen benefits your body and mind, it’s not a canner’s best friend. In fact, total package oxygen (TPO) can affect both your canning materials and your machines. In this blog post, we’ll explore how can-seam materials can impact your total package oxygen levels and what you can do about it.

But first:

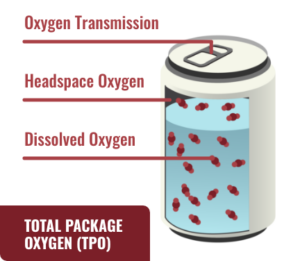

What is total package oxygen?

At RSS MACLIN, we support everyone in the food and beverage packaging industry, from micro-breweries to carbonated beverage giants. For those new to the industry, total package oxygen is the amount of oxygen that is sealed in a package. For cans, this includes:

- Dissolved oxygen: The oxygen that is dissolved in the liquid itself

- Headspace oxygen: The oxygen within the foam of a carbonated beverage

- Oxygen transmission: Oxygen that slowly permeates through the walls of the can

At RSS MACLIN, we’re committed to excellence.

How do can-seam materials affect TPO levels?

The materials used for can seaming are important to ensure low TPO and a high-quality seal. When exploring how can-seam materials affect TPO, we’ll look specifically at the compound, can body, and seam specifications.

Compound

Compound quality and consistency

When you’re trying to ensure a quality seam on your can, compound is crucial. It’s a vital part of the sealing process and ensures an airtight and secure seam with low TPO levels. Be sure to check the consistency of the compound to ensure optimal quality, since that can also impact the quality of the seam and the TPO levels.

Compound amount

In addition to the quality of the compound, it’s also important to ensure the right amount of compound is applied to each lid. For the best results, apply 26-32 grams of compound, depending on the diameter of the lid.

Can body

Materials

In the food and beverage packaging industry, aluminum is the material of choice, often selected for its corrosion resistance and lightweight properties. Over time, aluminum cans are susceptible to oxygen transmission, where the oxygen passes through the material and into the can’s liquid, increasing the TPO levels. For this reason, it’s important to use materials that are new, as the age of the material can impact the TPO levels. At RSS MACLIN, we recommend using lids that are no more than 2 years old, so as not to compromise the quality of the seal.

Can dimensions

At RSS MACLIN, we know that details matter. When you ask for scheduled or emergency service, we look at more than just the equipment. Your can’s dimensions are crucial to accurately determine the pin height so that the can seam is shaped and sealed correctly. To calculate the pin height, use the following equation:

Pin height = Raw can height – Chuck lip height – Material loss – Material deflection

Seam specifications

Curl height

The can seam’s curl height can help minimize TPO levels and improve the quality and integrity of the seal. While curl height varies according to the can’s dimensions, it’s important that seam technicians regularly inspect the seam quality and adjust as necessary.

Flange angle

As a critical aspect of the seam, the flange angle provides strength to ensure that the seam is able to withstand the internal pressure of carbonated beverages without compromising the seal. If the flange angle isn’t correct, the seam could leak, leading to increased TPO, decreased freshness, and possible product contamination.

Take your can seams to the next level

Don’t let inconsistent can–seam quality hold you back. Sign your team up for our hands-on can–seaming training to learn how to inspect, identify, and correct issues to ensure ultimate product freshness and customer satisfaction.