Master Setup Kit

Master Setup Kit

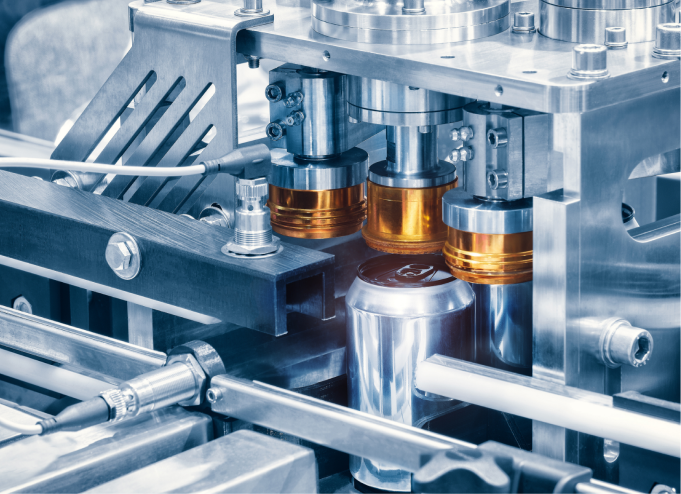

Our Best Tools for Efficient Seamer Adjustments

With the RSS MACLIN Master Setup Kit, you have our best specialty and supporting tools to check, change over, and make timing adjustments to the most common areas of concern on your seamer machines.

With more than a century of combined experience with can-seaming technology, the team behind the RSS MACLIN Master Setup Kit has created the ideal solution to increase your O.E.E. Now your team will have the power in their hands to stay up to speed.

Specifications

A Look Inside the Kit

- (3) RSS MACLIN Hollow Plugs (Size TBD)

- (1) RSS MACLIN 20” Drop-off Base with Dial Indicator

- (1) RSS MACLIN 4” Drop-off Base with Dial Indicator

- (1) RSS MACLIN Spring Pressure Quick-Set Base with Dial Indicator and Allen Wrench (cut to length)

- (2) RSS Spring Pressure Gauge Seaming Chuck Adapters (Size TBD)

- (1) Knock-out Rod Removal Tool

- (1) Spring Pressure Gauge

- (1) Dial Indicator Tip Extender

- (1) 1” Dial Indicator

- (1) RSS MACLIN Timing Plug

- (1) Toolbox

- (1) RSS MACLIN Pin height gauge with Dial Indicator (Size TBD)

- (1) Dial Calipers (Size TBD)

- (1) Roll Setting Mag Base with Dial Indicator

- (1) LG Magnetic Indicator Base

- (1) Dial Indicator Contact Tip Set

- (1) 12” Metal Feeler Gauge

- (1) 12” Plastic Feeler Gauge

- (1) 3” Tapered Feeler Gauge

- (1) RSS MACLIN Hand Wheel Handle (120/121L only)

- (1) Chuck Plate Fixture

- (1) RSS MACLIN Quickset Chain Fixture (Size TBD)

Request a Quote

Related Products

Explore related products to support your packaging line.

Timing Plug Kit

Spring Pressure Gauge Kit

Pin Height Gauge Kit

From the Blog

Explore the newest packaging line solutions added to our online marketplace.

The Benefits of Choosing an Expert Can Seamer Auditor

In the world of manufacturing and packaging, precision is paramount. This is especially tr…

Understanding Double Seam Can Defects: Types and Their Impacts

In the world of packaging, particularly in the food and beverage industry, the integrity …

Daily Preventative Maintenance for Can Seamers

Daily seamer checks will keep your seamer running smoothly and efficiently. Maintaining a…

Leave A Review

We want to hear from you. Tell us about the products you purchased or the service you received. Your feedback is important to us!

Education and Training

Become an Expert on Your Packaging Line

Help your facility stay more productive and avoid unnecessary downtime. Our training gives your team the skills to handle adjustments effectively and efficiently. Read about our available training options.