Monthly Guide for Can-Seamer Maintenance

June 17, 2024

Can-Seamer Maintenance

Performing regular monthly can-seamer maintenance checks is crucial to keeping your can seamer in top condition. By dedicating time to these important checks, you are being proactive and addressing any issues before they escalate. This saves your business time and money on repairs. With over 75 years of collective experience, we’ve gathered a detailed list of monthly maintenance checks to keep your can seamer running efficiently.

Monthly Maintenance Checks

Before beginning this monthly regiment, using your OEM manual, confirm that you have all oil weights and recommended gasket/sealant on site.

Oil Filtration System

First and foremost, always make sure your lubrication panel is clean and free of debris. This ensures an easier inspection of the system. Confirm there are no leaks, that flow is present, and if pressure exceeds the OEM recommendation to replace filters.

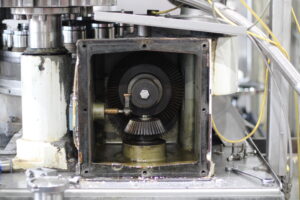

Gearbox Inspection

Check for Oil Levels

Check all gearbox oil levels in the can-seamer and add or replace oil as needed. Lubrication will extend the lifespan of the components and reduce friction. Also want to look for foreign liquid infiltration such as beer, water, sugar etc. in your oil.

Inspect Gears for Wear

If the gears show signs of wear, such as pitting or chipped teeth or backlash, evaluate, document, and photograph any issues for future modular repairs.

Motor and Drive System

Verify Motor Mounting and Alignment

To ensure functionality, verify the motor mounts and alignment. Inspect integrity of motor mount support. If time allows, use a dial indicator to verify the motor is properly aligned. This will be critical in keeping drive trains from developing backlash/premature wear.

Inspect Drive Belts for Tension and Wear

Inspect drive belts for tension and wear and replace them to maintain optimal performance. When reviewing your drive belts, look for splitting, cracking, chipping of belt cogs, as well as dry rot. If any of these conditions exist, replace belt before properly tensioning. *Pro-tip: If clearance is available and the assembly does not interfere, install additional cog belt to minimize downtime for future belt swaps.

Electrical System Check

Inspect Wiring for Wear or Damage

Inspect all wiring for cracks and the ability to be securely fastened. If time allows, replace said wiring or sensors if physical damage is present. Verify each whisker and Prox switch are illuminating properly and/or registering on the filler/seamer HMI.

Test Emergency Stop and Safety Features

A widely overlooked check is the functionality of all machine e-stops. Not only is it important to verify each one works properly, but that they register on the filler/seamer HMI accurately.

Schedule Preventative Maintenance

At RSS MACLIN, we offer comprehensive maintenance plans tailored to your specific needs. Don’t wait for issues to arise. Keep your can seamer up and running for many years by scheduling monthly preventative maintenance checks. Reach out to RSS MACLIN today, for a full-service solution to can-seamer maintenance.

Find a Can-Seamer Audit You Can Trust

Previous BlogNext Blog Title

Next Blog