The Importance of a Spring Pressure Gauge

April 4, 2024

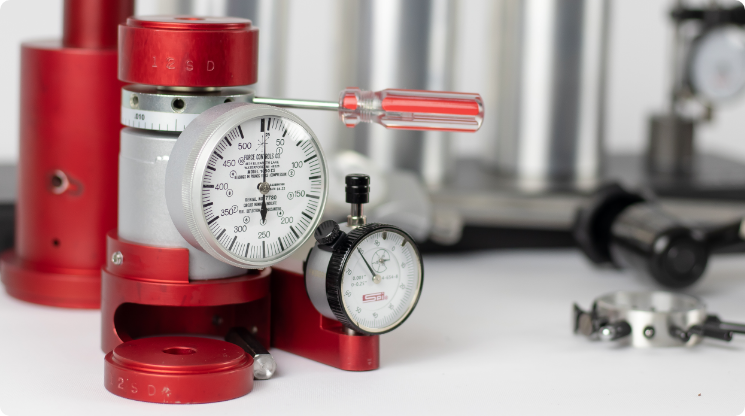

As a can seamer technician, you understand the critical role precision plays in maintaining the integrity of canning operations. Any inconsistencies in the sealing process can result in damaged cans, leading to costly rework and potential product recalls. One tool that can help you prevent such mishaps and ensure optimal performance is a spring pressure gauge. In this blog, we will explore why you should consider utilizing this essential instrument and how it can enhance your can seaming process.

Precision Maintenance

Using spring pressure gauges eradicates pressure variations inside your can seamer from station to station, thus creating consistent seams. By eliminating guesswork in lifter spring pressure adjustments, adherence to OEM specifications is upheld. Reliable pressure readings facilitated by these gauges translate to enhanced system accuracy.

Uniformity Assurance

Using spring pressure gauges eradicates pressure variations inside your can seamer from station to station, thus creating consistent seams. By eliminating guesswork in lifter spring pressure adjustments, adherence to OEM specifications is upheld. Reliable pressure readings facilitated by these gauges translate to enhanced system accuracy.

Quality Control

Accurate pressure monitoring is crucial for ensuring health, safety, and product quality. Seam variations in can seaming may compromise warranties, induce leaks, or pose safety hazards. Regular pressure monitoring afforded by spring pressure gauges enables prompt response to fluctuations, averting potential issues and optimizing operational efficiency.

Alignment with RSS MACLIN

Leveraging spring pressure gauges from RSS MACLIN minimizes downtime, reduces waste, and optimizes production processes to yield consistent, high-quality outcomes. Explore our comprehensive Spring Pressure Gauge Kit for further insights.

Discover what our Spring Pressure Gauge can do for you can-seamer line

With the RSS MACLIN Spring Pressure Gauge, you can trust that a vital aspect of the seam remains consistently precise, providing you with peace of mind throughout your operations.

Seven Benefits of Can-Seamer and Seam Analysis Training

June 23, 2023

Can seamers cause the most significant problems on the production line due to their critical role in ensuring the integrity of canned products. Seamer training is crucial in mitigating these issues and optimizing a facility’s throughput and output.

Seam analysis training educates individuals on the techniques and methodologies for examining and evaluating the seams formed during the canning process.

A well-trained workforce with the knowledge and skills to operate and maintain can seamers enhances production efficiency and maximizes output. By focusing on proper equipment setup, quality control, troubleshooting, and overall operational excellence, seamer training enables facilities to streamline their canning processes and achieve higher productivity levels.

Let’s explore some of the key reasons why you should consider training an essential component:

1. Minimizing Risks to Workers: Your team must comprehensively understand how to operate your can-seaming equipment correctly. You significantly reduce the risk of accidents and injuries by providing them with proper training. This includes crucial knowledge about identifying pinch points and employing safe practices when removing subassemblies. Training ensures that your team is well-equipped to prioritize safety protocols, reducing the likelihood of workplace incidents and promoting a secure working environment.

2. Minimize Risk to Consumers: Consumers who purchase canned goods with bad can seams may experience several issues. The faulty seams can compromise the integrity of the can, leading to leaks, contamination, spoilage of the food inside. In some cases, seam damage can result in sharp edges or jagged metal fragments protruding from the lid or body. Consumers may accidentally cut or lacerate their hands or fingers or mouth, leading to injuries that range from minor cuts to more severe wounds.

3. Cost Savings: While effective can-seamer equipment maintenance can indeed incur costs, the consequences of neglecting maintenance can be even more costly. Having a trained team that can proficiently identify issues enables them to perform preventative maintenance and promptly address repairs proactively without overspending. This approach significantly reduces overall maintenance costs, as well as detrimental dump product (which can dwarf maintenance costs on a single hold), allowing for a more efficient allocation of resources within your organization. By investing in training, your team can learn to mitigate potential problems, optimize the lifespan of your machinery, and achieve substantial cost savings overall.

4. Ensuring Quality: With expert training, you can uphold the highest standards of can-seam quality. This helps prevent leaks, product contamination, or compromised seal integrity, safeguarding the overall quality of your products.

5. Maximizing Efficiency: Through expert training, your team will gain a comprehensive understanding of efficiently setting up transfer points, drop-offs, chucks, rolls, and can-handling guides in your can-seaming equipment. This knowledge translates to reduced downtime, increased productivity, and improved throughput.

6. Troubleshooting and Maintenance: Expert training strengthens your team with the skills to swiftly identify and resolve common can-seaming issues. This saves valuable time, minimizes disruptions, and helps you maintain smooth operations.

7. Ensure Uninterrupted Operations: Empower your team with seamer expertise to overcome workforce changes. By equipping multiple workers with the knowledge to maintain and operate seamers, you avoid costly setbacks caused by employee turnovers and resignations.

Become a Can Seamer Expert

Numerous canning companies rely on external seamer service assistance. At RSS MACLIN, we aim to impart our industry expertise to you. Our training program empowers your team to become more self-sufficient and efficient in their operations.

The initial training serves as a solid foundation for your team. However, for continuous proficiency, it is highly recommended to undergo regular refresher courses. As the can packaging industry constantly evolves with innovations, staying updated with the latest can-seamer technology is crucial. By staying current with the advancements in the field, your team will be equipped to handle the dynamic challenges of the industry effectively.

Learn More

With a combined experience of over 75 years in packaging and can-seaming technology, our instructors at RSS MACLIN bring extensive expertise to the table. We offer flexible training options to suit your needs.

We offer in-house training, where your team can come to our facility and train on our equipment. This immersive training experience lets your team gain focused and uninterrupted insights into can-seaming technology without affecting your production output due to machine shutdowns.

Alternatively, our team can visit your facility and utilize your equipment for on-site training, providing hands-on instruction tailored to your specific setup. This approach allows your team to receive training in a familiar environment, maximizing the practical application of their newfound knowledge.

Regardless of your chosen training method, our instructors deliver high-quality instruction. They share their knowledge and experience to give your team the skills and aptitude to excel in can-seaming operations.

If you’re interested in training, you can learn more and contact us here.