Who We Are

RSS MACLIN is your go to production line service, focusing on the beverage packaging industry. After years of seeing how overlooked and unprioritized the inefficiencies of the seaming process were, RSS MACLIN came to fruition to fill a need in the industry to improve packaging equipment and operations. We realized we could help companies recover their most crucial asset: TIME. As the adage goes, “time is money.” Therefore, downtime is money lost. With our products and services, we can help any operation sustain as little production stoppage as possible.

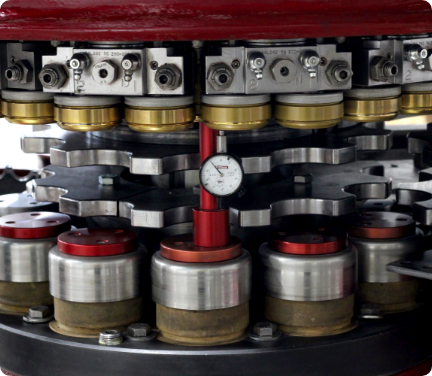

Packaging Experts

RSS MACLIN believes that one should never be complacent in one’s knowledge, and it is necessary to continue learning and growing at every stage. We have worked with the best in the industry and actively seek to pass along the need to understand and maintain equipment. Contrary to standard industry practice, we do not endorse the withholding of pertinent information for self-serving purposes. Bringing with us decades of procedural experience, along with an in-depth and intimate knowledge of the can-seamer machines, we know our work is our legacy that we eagerly wish to share with our customers.

Committed Partners

We want to grow with you as partners in producing the best and safest possible product for you and your customers. Our keen attention to detail helps your team ensure a safe, consistent and shelf-ready product. We are proud of our work and will never provide a product or a service that we are unwilling to sign our name on.

Globally Serving

We are dedicated to serving packaging companies across North America, including the United States, Canada, and Mexico. Recognizing the need to enhance the packaging industry with packaging equipment and operations, we established RSS MACLIN to help companies reclaim their most important asset – time.

RSS MACLIN

Owner & Founder

Anthony Ganni has been in the Food & Beverage industry for 48 years. His career started in 1973 as a Maintenance Technician (Carnation, Schlitz Beer) before taking a Maintenance Manager position at PepsiCo. By 1984 he began employment at Anheuser Busch as a Maintenance Supervisor. In his 24 years at AB, he climbed the ranks to Overhaul Supervisor, Maintenance Area Manager, and ultimately ending with him as the Seamer and Can Filler Corporate SME. Following a brief retirement stint, he decided to reenter the industry as the Training Manager at Pneumatic Scale Angelus. Anthony again saw rapid growth and opportunity in the company as he was promoted to Director of Training, Global Training Manager, finally becoming the Director of Seaming Technology until 2018.

His tenacity and dedication to the industry are apparent, looking at the trajectory of his career and the numerous awards and accreditations for the processes and improvements he implemented. He created RSS MACLIN to take everything he has learned and all of the initiatives he pioneered to pass on as his legacy and forever leave a mark on the industry. Anthony looks forward to bringing this guarantee to every job- “I push the importance of being thorough, double-checking work, and keeping everything set to specification. I am overly attentive to detail and make sure I do a quality job to ensure you do a quality job.”

QUALITY IS HIS PHILOSOPHY.